Surface-Mount Device (SMD) components are at the core of modern electronics, enabling the production of compact, efficient, and high-performance devices. Among the many types of SMD components, SMD LEDs are especially crucial in lighting, displays, and indicator systems. However, understanding the key concepts of SMD components and SMD LED polarity is essential to ensure proper assembly and functionality.

In this article, we will explore SMD components, their role in PCB assembly, and the importance of SMD LED polarity in ensuring reliable performance.

What Are SMD Components?

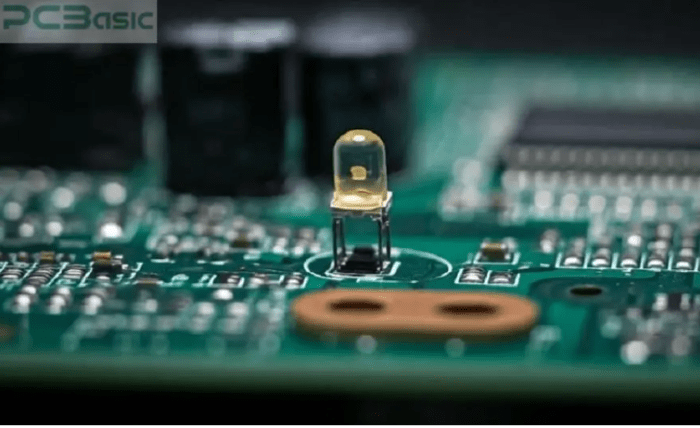

SMD components are electronic components designed to be mounted directly onto the surface of a PCB, unlike through-hole components which require holes to be drilled in the board. SMD technology has become the standard in the electronics industry due to its advantages in size, performance, and ease of automation.

Types of SMD Components

SMD components come in various types, each serving different functions. Some of the most commonly used SMD components include:

- Resistors: SMD resistors are used to limit the current in a circuit. They are available in various sizes (e.g., 0805, 0603) to suit different PCB designs.

- Capacitors: SMD capacitors store electrical energy and are used for filtering, smoothing voltage, or coupling signals. Ceramic and tantalum are the most common types used in SMD designs.

- Inductors: SMD inductors are used to store energy in a magnetic field and are widely used in power supplies and signal processing applications.

- Diodes: SMD diodes are used to control the flow of current in one direction. These include rectifiers, Zener diodes, and Schottky diodes.

- Transistors: SMD transistors are used to amplify electrical signals or act as a switch. They are critical in logic circuits and power regulation.

- LEDs: SMD LEDs are widely used in displays, indicators, and backlighting applications due to their compact size and energy efficiency.

- Integrated Circuits (ICs): These include microchips and other functional components that integrate multiple electronic functions into a single unit. Common types include SMD capacitors, SMD resistors, and SMD transistors.

The Importance of SMD Components in Modern Electronics

The rise of SMD components has revolutionized the way electronic devices are designed and manufactured. Some of the key benefits of using SMD components in PCB assembly include:

- Compact Size: SMD components are significantly smaller than traditional through-hole components, enabling the production of smaller and more compact devices. This is especially crucial in consumer electronics, such as smartphones, wearables, and medical devices.

- Automated Assembly: SMD components are well-suited for automated placement and soldering processes, making them ideal for high-volume production. This results in faster manufacturing times and reduced costs.

- Improved Performance: Due to their smaller size and efficient design, SMD components typically offer better performance, including faster signal transmission and improved power efficiency.

- Cost Efficiency: SMD components are generally more cost-effective to produce, which translates into lower overall manufacturing costs for PCBs.

What Is SMD LED Polarity?

One of the most critical aspects of working with SMD LEDs is understanding their polarity. LEDs (Light Emitting Diodes) are diodes, meaning they allow current to flow in one direction only. Incorrectly placing the LED in the circuit can result in a malfunction or complete failure of the component.

Understanding Polarity in SMD LEDs

The two terminals of an LED are called the Anode (positive) and the Cathode (negative). Proper orientation is crucial for the LED to function correctly.

- Anode (Positive Terminal): The anode is the longer lead of the LED, and it is where the positive voltage is applied.

- Cathode (Negative Terminal): The cathode is the shorter lead of the LED, and it connects to the negative side of the circuit.

In SMD LEDs, polarity is indicated in several ways to ensure proper assembly:

- Markings on the PCB: Most PCBs are designed with clear markings to indicate the orientation of the LED. This might include a polarity symbol, a square pad for the cathode, or a round pad for the anode.

- Markings on the SMD LED: Some SMD LEDs themselves have polarity indicators, such as a flat edge on the side or a mark on the cathode to signal the negative terminal.

- LED Color: In some cases, different LED colors (such as red or green) can have different voltage requirements and polarity markings, making it even more important to follow correct placement procedures.

Why Polarity Matters

If the polarity of an SMD LED is reversed, the current will not flow properly, and the LED will fail to emit light. Furthermore, if an incorrect current is applied, the LED may be damaged or destroyed. Therefore, understanding SMD LED polarity is essential to:

- Prevent Circuit Damage: Incorrect polarity can cause short circuits or irreversible damage to the LED.

- Ensure Proper Functionality: Correctly aligning the LED ensures that it works as intended, producing light and contributing to the overall functionality of the electronic device.

- Increase Product Lifespan: Ensuring correct polarity helps to prevent early failure of LEDs, increasing the overall reliability of the product.

How to Identify and Correctly Install SMD LEDs

To ensure correct installation of SMD LEDs in your PCB assembly, here are a few best practices:

- Examine Polarity Indicators: Check the polarity indicators on the PCB and the SMD LED itself. These indicators can include a flat edge on the LED or marks on the component pads.

- Use Visual Aids: During assembly, use visual aids such as magnification tools or a magnifying lamp to ensure the LED is correctly oriented. This step is particularly helpful for small-sized SMD LEDs.

- Test Before Finalizing: If possible, test the circuit before finalizing the soldering to confirm that the LED works correctly and that the polarity is properly aligned.

- Follow Manufacturer Guidelines: Always refer to the datasheet or specifications of the SMD LED to understand the exact orientation and requirements for installation.

Conclusion

SMD components and SMD LED polarity are essential concepts in modern PCB assembly. SMD components enable compact, efficient, and cost-effective designs, and understanding LED polarity is critical to ensuring proper function and longevity of electronic devices. Whether you’re working with resistors, capacitors, transistors, or SMD LEDs, correct placement and assembly are crucial for optimal performance.

As the demand for smaller, faster, and more reliable electronics continues to grow, mastering the handling of SMD components and understanding LED polarity will continue to be a vital skill for PCB manufacturers and designers.

By following proper installation procedures and staying informed about best practices, you can ensure your PCBs are both high-performing and reliable, meeting the demands of today’s advanced technology.